|

| KA606 |

|

| KA345 |

The reason the KA606 did not fit was due to the design of the 06-07 ZX-10R for which it was made. The 06-07 ZX-10R was the only model with a big heavy under tail exhaust on the right side of the bike so the reservoir had to be offset quite a bit to the left to clear the hot pipes. The KA345 on the other hand was made for the 04-05 ZX-10R which had a conventionally mounted exhaust. This conservative exhaust position allowed for a nuetral reservoir position.

|

| Bottom clevis with unmodified shock linkage sleeve |

|

| Top mount bushing with ZX-7R upper shock mount |

|

| KA601 clevis compared to the KA606's |

|

| KA601 top mount bushings compared to the KA606's |

The top mounting bushings were little tricky to get out. They were a split design that needed to be hammered out with a drift. A nice drift with sharp corners were neccessary to avoid damage.

|

| Drifting out the split bushings |

|

| Bushings hammered out |

One specification of ZX-10R shocks in general that worried me was the shock length. ZX-10R shocks in general were 338mm tall vs 348mm for the ZX-7R. The 10mm height difference could have a significant impact on handing. While it was possible to make up for this height difference with shorter shock linkage arms (AKA dog bones) and the ZX-7R upper shock mount, I thought it was best to dial out as much of the difference in shock lengths as possible on the shock itself.

Although it was possible to get the KA345 shock length to match the OEM item, the bottom clevis needed to be turned out right to the limit of what the manual said was safe. I decided safety was more important than razor sharp handling and turned the clevis in a few turns.

|

| 12 exposed threads is the maximum adjustment for this clevis |

With the neccessary adjustments made, the shock slid into the bike through the top with the battery tray removed.

While I have yet to ride the bike with the KA345 installed, I can report today that the Ohlins is much lighter than the stock shock.

Yes sir, thats a whole 1.5lbs saved. I'm not sure if this is sprung weight or unsprung weight but every ounce counts right?

Another little weight savings thing I did was use the axle from a 06-07 ZX-10. Recall that the FG352 I have on my bike right now were designed for that bike.

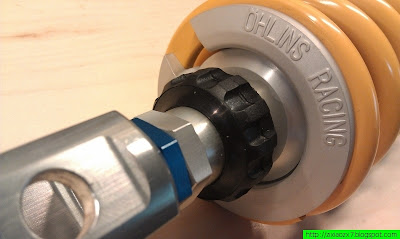

Even though the ZX-10 axle required sleeves and a special Ohlins nut, it still managed to be lighter. Not much but once again every ounce counts... and this time I'm sure it's unsprung weight. Unfortunately the weight savings here may be balanced out by these little beauties.

While these Muzzy block off plates are lighter than the entire clean air injection system, they are heavier than the OEM covers.

|

| My buddy Alok helping me scrape off the paper gasket |

|

| Liquid semi-drying Three Bond 1194 sealant |

|

| Muzzy block off plates installed |

|

| These plates clean up the engine bay nicely |

The accute reader will notice I am running CVK carbs because I'm still sourcing some float bowls for my FCRs. More than anything else though, I'm looking forward to just riding the bike this season and not getting caught up in projects mid-season.

The only major component that I need before the bike is road-worth is a new set of triples from Dan Harvy because the original ones had some chatter marks in the lower right bore which caused clamping issues. Dan's hard at work getting me a new set so I'm very excited.

Here are some rainy pics of the bike as it sits now. Enjoy.